Graphite filled PTFE has exceptional chemical resistance to corrosive environments and it is compatible with the most hydraulic fluids.Graphite Filled PTFE exhibit good initial wear and rubbing/sliding characteristics in dry and water applications. Excellent performance when used for hydraulic or pneumatic compression type rod and piston seals, bearing bands and rotary applications. Graphite is commonly blended with carbon and PTFE (Teflon)

Advantages:

• Higher flexural modulus and surface hardness than unmodified PTFE.

• Low coefficient of friction compared to other filled PTFE materials

• Exceptional chemical resistances to corrosive environments

• Good wear resistance in dry or wet environments

Application:

• Compression rods

• Wear strips

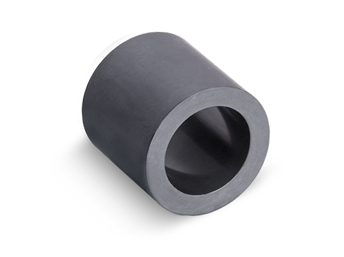

• Bushings

• Bearings

• Seals., etc

Data sheet

|

Property |

Test Method |

Values |

|

Specific Gravity |

ASTM D 4894 |

2.1-2.3g/cm3 |

|

Tensile Strength |

ASTM D 4894 |

9-12 mpa |

|

Elongation |

ASTM D 4894 |

120 % |

|

Shore D Hardness |

BS EN 13000-2 |

55-60 |

|

Temperature Range |

- |

-200 oC - 260 oC |

|

Material |

- |

15% graphite powder+PTFE |